How Can Six Sigma Be Beneficial to an IT Project?

Any organization or business would want to improve the capability of their business processes. To do this, it needs a suitable tool that will ensure they get the desired results. Six-sigma is an approach, a methodology and a discipline that enhances reduction or elimination of defects involved in manufacturing and transactional processes. It does this by trying to drive towards six deviations about the nearest specific limits and the mean.

Six Sigma employs a quantitative approach for the improvement of defined metrics in financial, manufacturing and service processes. It works by increasing the performance and reducing the variation for the growth in a firm’s profit margins, quality of products and services, reduction in loses and improvement in employees’ morale.

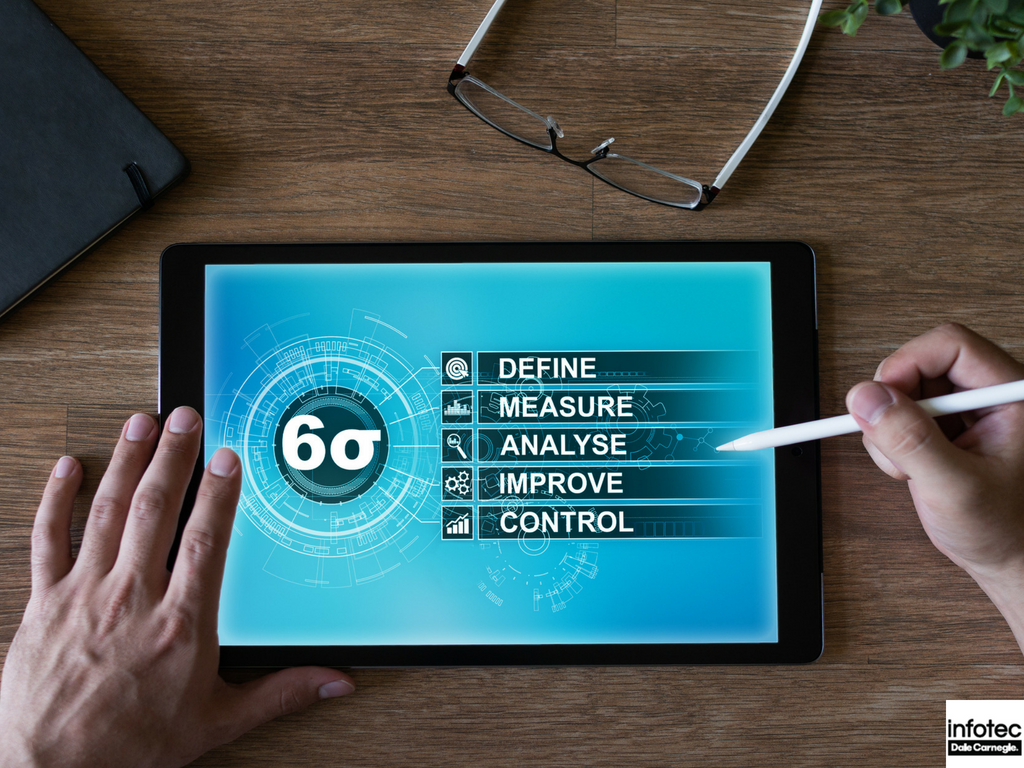

Six Sigma Process

This is a form of data-methodology or process used by organizations to eliminate unknown defects in their operation. It is a form of statistical process that allows an error of 3.4 and less per a million opportunities. Being a process that is designed to solve a problem. Sigma process consists of some primary stages with DMAIC as the acronym:

- Define: Definition of the problem

- Measure: Mapping out the current process

- Analyze: Identifying the cause of the problem

- Improve: Implementation and verification of the solution

- Control: Maintenance of the solution

Before beginning Six Sigma process, it is required to choose a project that is good for improvement. It can be:

- Any known problem within the process,

- Project with the potential to result in increased revenue or minimized cost

- Efficiency

- A project that has collectable data

Six Sigma can also provide a guideline for the selection of the right project that may lead to reduced costs, maximization of profit, and improved collaboration.

Six Sigma and IT

A number of IT firms seem to be trim and vigorous in they're day to day running of their businesses. Employing Six Sigma in your IT firm will lead to a reduced number of servers, timely call responses and improved project delivery.

Prior to the introduction of Six Sigma, most IT projects got into insatiable demands and lost ROI. Six Sigma came in handy and made it easy to precisely demonstrate what real technological value is and also in the improvement in the delivery of the said value. It has improved quality in IT industry and can come to the aid of exhausted employees and stressed-out managers. Six Sigma has proven to lead to error reduction by becoming a transformational tool in the IT business.

Six Sigma Training

To improve your business processes, you need Sigma to analyze and come up with a solution to quality problems. The training and certification help the organization with the aspects required for the implementation stages. It also champions for the accreditation of the trainees/ employees at various levels of the belt. The training takes a maximum of three months.

Principles of Six Sigma Training

Six Sigma training operates on some principles. These principles are business transformation-related.

- Focus on the customer

- Enhancement of the work stream

- Management and improvement of the process flow

- Reduction and removal of waste

- Based on facts to reduce variation

- Equipping and involvement of each person involved in the process

- The systematic undertaking of improved activities

Why you Need a Six Sigma Process in your Business

Incorporating Six Sigma within your organization or business will bring along the following benefits:

- Improved customer loyalty: it helps determine the successes of an organization. It may help reduce risks of dissatisfaction among customers.

- Time management: Employing this methodology can help in enhancing proper time management, which may result in more efficient and productive employees.

- Strategic planning: Helps a firm to focus on the significant areas that need implementation.

- Reduced cycle time: Teams can be used to identify negative issues that may cause long time cycles.

- Supply chain Management: May use the methodology to lower the number of suppliers thus reducing the number of defects that may be in place. To accommodate changes in the supply chain, it is a great idea to drive Six Sigma improvements in your firm.

- The motivation for your employees: Six Sigma comes with problem-solving tools that will ensure your employees get the right motivation and development thereby creating a conducive environment for work and business.

Six Sigma is a vital tool that you need to employ in your business if you want to reduce or eliminate waste, minimize resource usage, and to improve efficiency. Contact Infotec and let your employees have the Sigma skills needed for your business growth.

For more information about Infotec or any of our programs click here: http://www.infotectraining.com/ or https://ops.infotecpro.com/course_schedule/course_schedule.cfm.